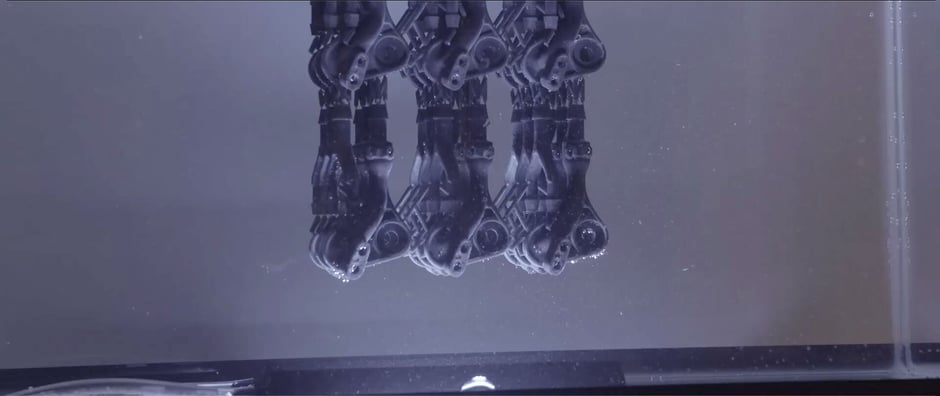

High Density Part Stacking – Supporting Batch-Run Productivity

"By stacking parts we are able to print in batches of 100, and have reduced the time it takes to prepare a build by 80%. The combination of stacking and production-grade materials makes Figure 4 ready for production."—Gregoire Mercusot, Materials Engineer, ADDLAB, Decathlon

Solutions to Boost Your Additive Plastics Productivity

Figure 4 Standalone

Ultra-fast and affordable for same day prototyping and low-volume production

Figure 4 Tough 60C White

White plastic for long-term use parts with a good combination of impact strength, elongation, and tensile strength

Figure 4 Tough 65C Black

Black plastic for long-term use parts with a good combination of impact strength, elongation, and tensile strength.

The superior isotropic nature of 3D Systems' Figure 4 3D printing technology and materials allows for extra degrees of freedom in preparing parts for optimal print quality and print efficiency. As a result, parts do not need to be oriented in a special way to achieve the highest mechanical properties – which means parts can be tightly stacked for maximum space utilization and volume efficiency.

The superior isotropic nature of 3D Systems' Figure 4 3D printing technology and materials allows for extra degrees of freedom in preparing parts for optimal print quality and print efficiency. As a result, parts do not need to be oriented in a special way to achieve the highest mechanical properties – which means parts can be tightly stacked for maximum space utilization and volume efficiency.