More than 35 years ago, Chuck Hull’s curiosity and desire to improve the way products were designed and manufactured gave birth to 3D printing, 3D Systems, and the additive manufacturing industry. Since then, that same spark continues to ignite the 3D Systems team as we work side-by-side with our customers to change the way industries innovate. As a full-service solutions partner, we deliver industry-leading 3D printing technologies, materials and software to high-value markets such as medical and dental, aerospace, space & defense, transportation & motorsports, AI infrastructure, and durable goods. Each application-specific solution is powered by the expertise and passion of our employees who endeavor to achieve our shared goal of Transforming Manufacturing for a Better Future.

Industrial

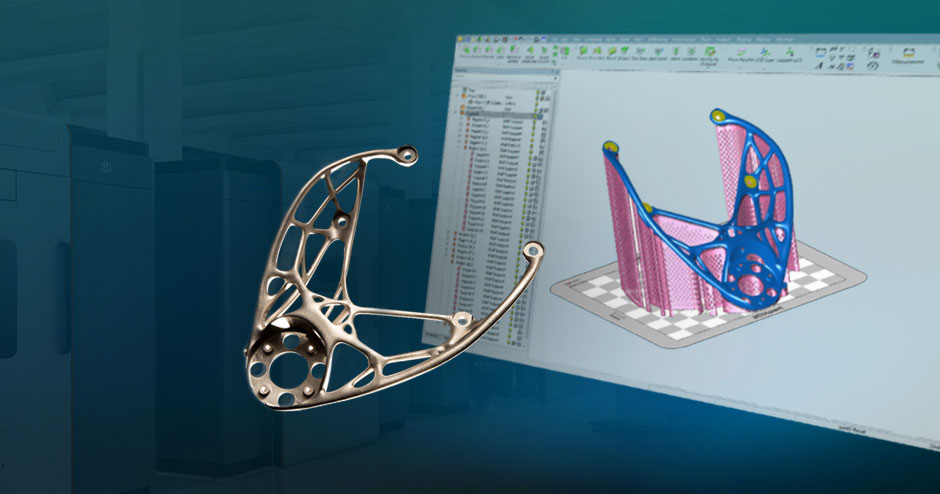

Our additive manufacturing solutions are widely used in advanced industrial applications to drive performance improvements. Industry-specific guidance from our in-house experts helps our users maximize the results and returns of choosing this technology.

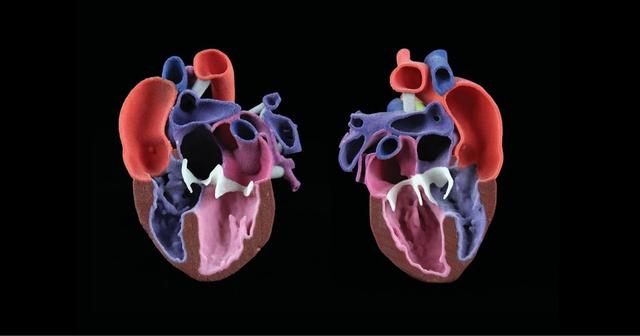

Healthcare

Additive manufacturing solutions are a natural fit for healthcare applications, where customized designs and high performance are in demand. With a dedicated healthcare facility and application experts across the globe, we are proud to help improve patient outcomes.

Our History – From Chuck Hull’s Idea To An Industry

3D printing is invented by 3D Systems’ co-founder, Charles (“Chuck”) Hull. The patent for Stereolithography Apparatus (SLA) is filed, and 3D Systems launches as the first ever 3D printing company, commercializing the SLA-1.

Chuck Hull creates the first-ever 3D printed part, inventing Stereolithography

Additional 3D printing technologies come to market, expanding material options and capabilities. Parallel advancements in 3D software continues to change the landscape of design. 3D printing offers major time savings as a prototyping technology.

Commercialization process starts for ColorJet Printing (CJP) class of 3D powder-based systems

3D Systems brings MultiJet Printing (MJP) 3D printers to market

Alongside continued technology advancements in hardware, software developments continue to evolve to support an integrated workflow. Highlights include the release of the first Simbionix virtual reality surgical simulator, and the emergence of scan-based design software for reverse engineering.

Advancing software tools enhance the design freedom of additive manufacturing workflows.

3D Systems experts help customers expand applications for additive manufacturing into production. The company adds direct metal printing (DMP) to its portfolio and production-capable plastic printing platforms designed to scale.

3D printed metal tube holders produced using 3DXpert software and Direct metal printing

Our engineers continue to advance our portfolio of solutions, and collaborations with our application experts continue to drive innovation across industries. Visit our press room for the latest news and developments.

3D bioprinted trachea model (Image courtesy of United Therapeutics)